≡

One autumn rain and one cold, ten autumn rains require wearing cotton.

With the gradual arrival of autumn and winter festivals, the selection and construction requirements for foam adhesive have also become higher. Foam adhesive is cured by chemical reaction with moisture in the air. If there is less moisture in the air and the ambient temperature for reaction is low, its curing time and cured foam performance will be greatly affected.

In late autumn and winter, due to the influence of cold air in most parts of China, the air is dry and the temperature is low, and the construction environment is poor, which brings great difficulties to the use of foam adhesive. If the quality of the selected products is poor or the construction is improper, it will cause slow curing, voids, weak bonding and other phenomena of foam adhesive, which will affect the construction quality.

Precautions for using foam adhesive in autumn and winter seasons:

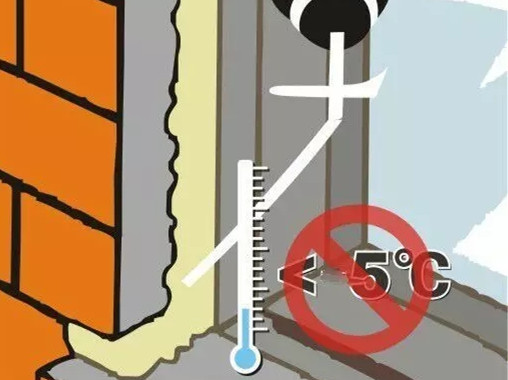

1. Storage temperature: The storage temperature of foam adhesive should be above 5 ℃.

2. Construction temperature: The normal operating temperature for foam adhesive is+5~+35 ℃, under which the product's performance can be fully utilized. Therefore, users are advised to create good usage conditions for the product under low temperature conditions as much as possible.

3. Reminder: When working at low temperatures, it is recommended to place the product in warm water at 25-30 ℃ for about 5 minutes before use to increase the temperature of the tank to ensure its performance. However, it is important not to heat it too high or directly contact it with an open flame.

Precautions during construction:

1. Floating dust and oil stains on the construction surface can affect the bonding effect of the foam adhesive. Therefore, before construction, the construction surface should be cleaned appropriately to ensure good bonding effect.

2. Foam adhesive is a wet curing product. Spray a little water on the construction surface before construction to improve the environmental humidity, which can significantly shorten the curing time and improve the overall quality of foam.

3. When installing wooden doors with foam adhesive, it is necessary to properly fix and support the door frame and leaf before and after installation to avoid deformation.

4. After filling the gap between the door frame and the wall with foam adhesive, there should be no external force within 24 hours, otherwise it may cause displacement, loosening, or even detachment of the wooden door in the later stage.

It is recommended to choose products with stable quality during autumn and winter seasons to avoid losses caused by the use of low-quality products with added powder. Through years of research and manufacturing, Santai Rubber Industry has accumulated rich technology and experience. In response to harsh conditions such as deep autumn, dry winter climate, and low temperatures, four major technologies have been adopted to improve product performance and upgrade products in various aspects.

1. Improve the crispness and brittleness of low-temperature foam: due to the low temperature in winter and the low low-temperature activity and slow curing of foam products, the foam can not be fully cured for a long time after being hit, resulting in crispness and brittleness, which not only seriously affects the construction progress, but also leads to serious quality problems. Santai adopts advanced technology to basically eliminate the phenomenon of foaming glue becoming crispy and brittle under low temperature conditions.

2. Improve the pressure balance in the foam tank and greatly reduce the remaining foam in the tank: the temperature is low in winter, if the formula is unreasonable, many foam will not be cleaned under low pressure, and in serious cases, more than 5% of additional materials will be wasted. Santai has optimized the formula in various aspects, making it easy to clean the foam even at low temperatures.

3. Accelerate deep curing and improve cavity phenomenon: under low temperature and dry conditions in winter, due to the lack of water vapor, the curing speed of foam foam is very slow, and it is easy to have large cavities. Tai adopts advanced technology, which can greatly accelerate deep solidification and eliminate or greatly improve the phenomenon of voids.

4. Adopting a unique formula system to enhance storage resistance at low temperatures: In special northern regions, the temperature often drops below minus 20 degrees Celsius during winter, and at low temperatures, the performance of the foam adhesive will significantly decrease. Santai has upgraded the winter foam formula in various aspects, which can greatly reduce the adverse effects of low temperature on foam storage.

If higher bonding strength is required according to construction requirements, it is recommended to choose our company's flagship product.

The difference in adhesive effect between Santai engineering material and ST-5 material in the same environment:

Adhesive effect after being taken out of the low-temperature warehouse

(There is no heating on site, and the indoor temperature is around 5 ℃)

After being taken out of the low-temperature storage warehouse, it is stored in the same place

After being placed on site for three hours, the adhesive effect will be applied

Under the same environment and humidity, long-term storage and immediate use under low temperature conditions can cause problems even if the construction site temperature is high. When using glue in winter, in addition to ensuring that the ambient temperature is above 5 ℃, products taken out of the warehouse must be placed in a suitable temperature place for a period of time or fully soaked in warm water before meeting the usage requirements.

Santai Rubber Industry reminds you:

The higher the product grade, the better the quality, and the stronger the adaptability to low temperatures!