≡

During the drill, four groups were established: the Public Security Alert Group, the Emergency Repair Group, the Logistics Support Group, and the On site Rescue Group. Under the overall coordination of the drill commander, each group performed its own duties, had clear division of labor, closely cooperated, and successfully completed the entire emergency rescue process with scientific and effective response measures. Each link was connected in an orderly manner.

During the process of unloading dimethyl ether, the operator climbed onto the liquefied gas storage tank platform for inspection. At this time, the unloading crane pipe at the unloading position fell off, causing a large amount of dimethyl ether to leak. The driver promptly pulled up the emergency cut-off rod behind the tanker and evacuated urgently. When the operator discovered the leak, he forcibly closed the unloading crane pipe valve and inhaled a large amount of dimethyl ether gas, resulting in coma. Using this as a drill scenario, conduct a comprehensive emergency rescue plan drill.

1. The unloading crane tube fell off, and a large amount of dimethyl ether sprayed out from between the tanker and the crane tube. The driver saw the situation and promptly pulled up the emergency cut-off lever behind the tanker before evacuating urgently.

2. The operator ran off the platform upon seeing the situation and tried to close the valve. However, he did not wear a gas mask and inhaled too much dimethyl ether, causing suffocation and fainting.

Thick smoke filled the drill site

The workshop alarm emits sound and light alarms

Organize emergency evacuation of personnel in the polyurethane sealant workshop

1. The emergency duty room alarm sounded, and the duty officer saw the alarm information, checked the monitoring, and found a large amount of thick smoke in the dimethyl ether tank area. He immediately reported to the department leader.

2. The department leader walked from the inner office to the control room to check the accident information and reported the dimethyl ether leakage accident to the main leaders of the company, and issued warning information as required;

Mr. Su rushed to the duty room, inquired about the accident situation and checked the video surveillance, and announced the activation of the company level emergency rescue plan.

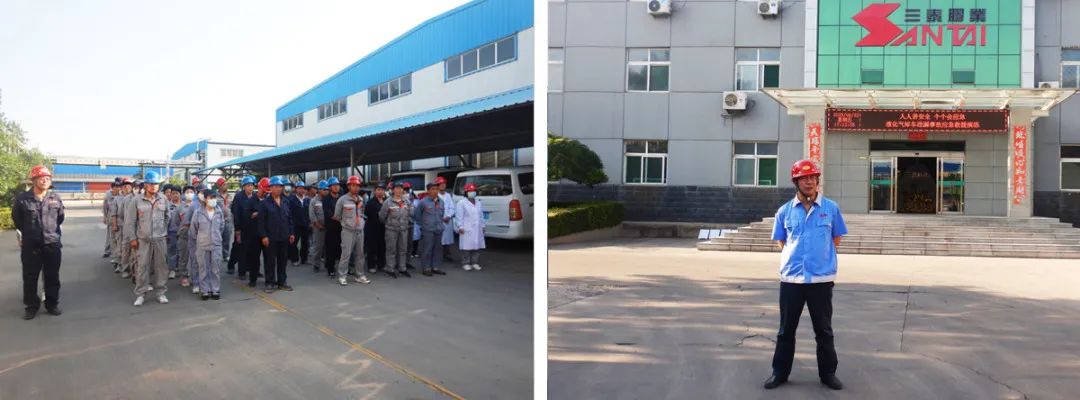

Each group rushed to the scene of the accident as quickly as possible

1. The members of the security team are in place, a cordon is set up and a dedicated person is assigned to guard the scene. Unauthorized personnel are strictly prohibited from entering or leaving the accident site.

2. After the leader of the rescue team led some members of the rescue team to the scene, they immediately arranged for the members to wear firefighting combat uniforms and air respirators, and carried out rescue operations according to the arrangement.

3. The logistics support team organized personnel to urgently transport equipment such as air respirators, gas masks, and firefighting suits from the fire station to the outskirts of the storage tank area.

4. The emergency repair team rushed to the scene to rescue the injured.

5. The on-site rescue team members carried the injured into the ambulance.

The security alert team will urgently evacuate all unrelated personnel to the north gate of the factory and count the number of people

Emergency repair team's fog cannon dilutes combustible gas

The accident scene has been controlled: the concentration of combustible gases in the air at the scene has decreased to below 10% LEL, the power supply of the equipment has been cut off, and the equipment switch valves have been further manually closed. The accident has been effectively controlled.

Chairman Su's comments on the drill site

Through this drill activity, the practicality and operability of the emergency plan were further tested, and the collaborative response level and practical ability of emergency rescue organizations and emergency rescue teams were exercised. The goal of testing the plan, training the team, strengthening the safety awareness, self-protection ability, and emergency response ability of all employees was achieved, which played a positive role in enhancing the emergency rescue capability for production safety accidents.

This drill has been affirmed by the chairman, and relevant opinions and suggestions have been put forward for the shortcomings of this drill. He emphasized that "being prepared means no danger, and being far sighted can solve immediate problems". Safety production work must be prepared in advance, and the foundation of emergency management must be consolidated. The key is to implement various risk prevention and control measures in order to avoid or reduce accidents. Strengthening emergency response capacity training, everyone being able to respond to emergencies scientifically and effectively, can minimize the losses caused by accidents to the greatest extent possible.